The Best Guide To Dust Extractors For Small Workshops

More About Dust Extractors For Small Workshops

Table of ContentsDust Extractors For Small Workshops Can Be Fun For AnyoneDust Extractors For Small Workshops - An OverviewRumored Buzz on Dust Extractors For Small WorkshopsDust Extractors For Small Workshops Fundamentals Explained

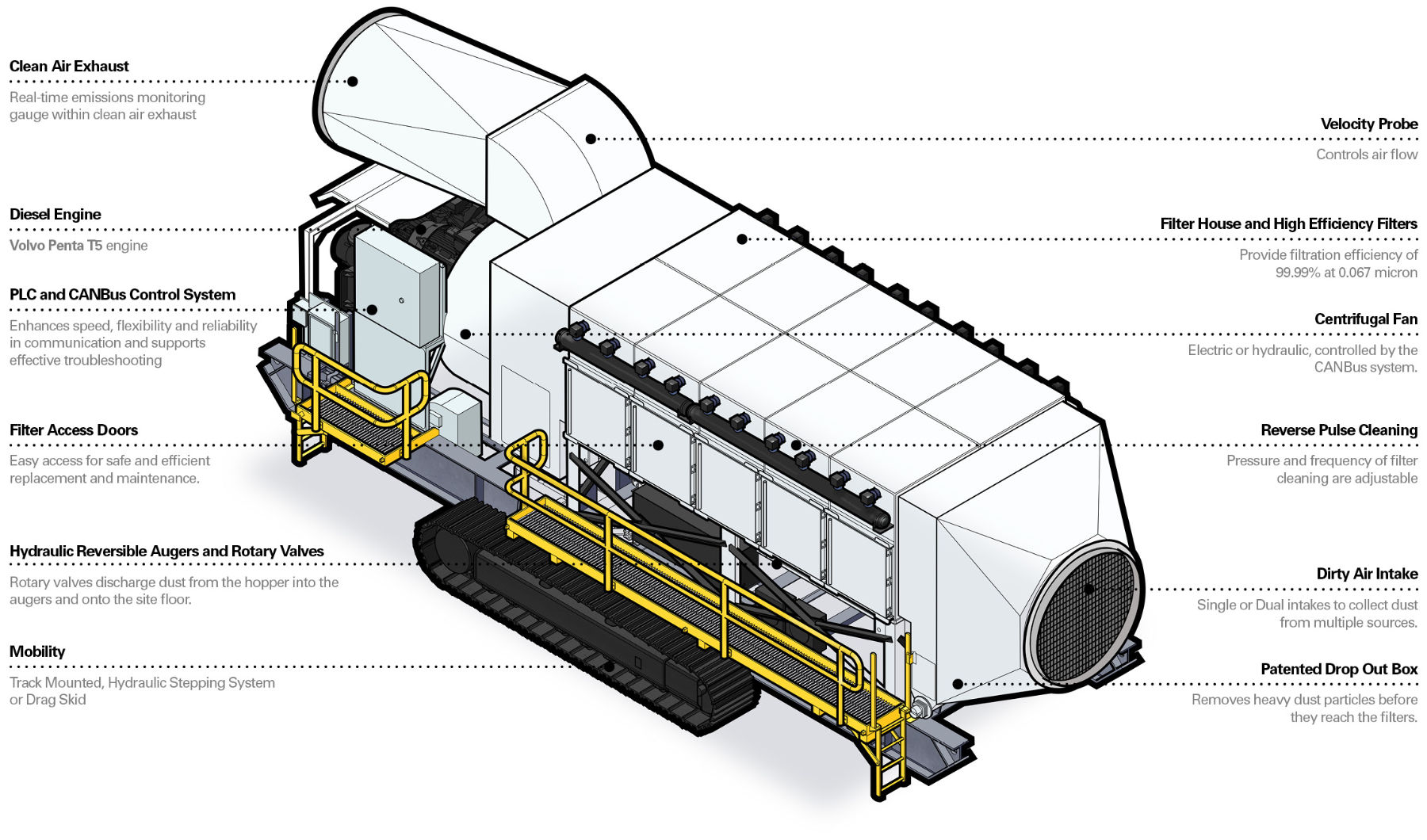

The challenges for factory dirt collection systems revolve around crystalline silica dust, carbon monoxide gas, and also heat, which are hazardous combinations. These aspects make meeting air quality requirements hard and requiring. For that reason, when choosing a dust control system for a foundry, the first consideration is the capacity of the device to hold up against rough and also harmful work environment conditions.

Covering, or thermal spray, uses warmed product to metals to layer their surface areas. Dirt collection systems for this sort of operation need to be particularly designed to fit the kind of coating being used. The function of the system is to regulate and also lessen overspray and also dirt. The normal thermal spray dust control system uses air ducts to move air to the collection tool. dust extractors for small workshops.

Though it would seem most likely to boost air movement as well as motion, this kind of solution may be inefficient and also waste power. The layout of the cubicle depends on the pressure of the air getting in the cell or cubicle. For most systems, it is essential to have a slight vacuum in the cubicle to prevent feasible positive stress.

The Basic Principles Of Dust Extractors For Small Workshops

An additional technique is simply placing the makeup air link on the top of the cubicle. No matter of the layout, it is essential for the cleansing of the air to have cross air flow. Much like a cleanroom, air movement in a thermal spray booth can be either straight or downward, though the descending design is best for dirt collection systems.

The pharmaceutical market is a highly managed market with substantial and also specific regulations. Dirt from drugs is produced primarily during the manufacturing and also product packaging of products. Each step of generating a drug, which includes granulating, drying, mixing, pushing, finishing, and grinding, generates large quantities of dust that need to be eliminated.

Obstructing as well as controlling this circulation is the function of the dust control system. When designing a dirt control system for a pharmaceutical plant, the initial consideration is mapping the ventilation system to track the path of dust, fumes, existing airflow patterns, and also feasible evolutionary modifications. Because numerous pharmaceutical dusts are flammable, the style of the ventilation system is exceptionally crucial.

HEPA filters are typically located in pharmaceutical dust control Get More Info systems given that they are the most efficient as well as reliable. Similar to a factory system, they are installed as a second protection to achieve zero emissions. Recycling creates a terrific offer of dirt as an all-natural outcome of diminishing things to their raw materials.

The Basic Principles Of Dust Extractors For Small Workshops

Dust comes from after products are shredded, squashed, or have paint or lacquer got rid of. All recycling facilities are required to follow air quality criteria. As they work to satisfy top quality criteria and control pollutants, they have identified that dirt control is a significant problem, leading to the wide use dirt collection systems to alleviate as well as have the problem. dust extractors for small workshops.

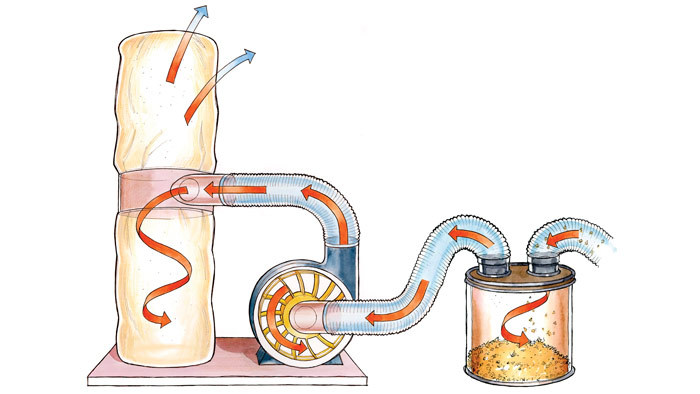

When manufacturers pick a dirt control system, they are suggested by manufacturers concerning the sort of system that would best fit their demands considering that acquiring and setting up a dirt control system is a major investment. Particulate matter can be found in a variety of types, from silicon dust to timber chips as well as sawdust.

Rumored Buzz on Dust Extractors For Small Workshops

Material filter bags in a cartridge system are the most efficient approach for gathering dust. Dirt collection systems are covered to include the dirt as well as clean the air.

Plastic Dirt High-Density Polyethylene (HDPE) dust is created in the production of plastic panels when they are designed as well as based on a side trimmer, mill, or miter saw. Paper Dust One of the more usual kinds of dust is paper dirt, the side effect of the a knockout post manufacturing of various kinds of paper.

With the introduction of dirt collection systems, workers are much safer and a lot more protected. Sugar Sugar dirt is the spin-off of the manufacturing of sweet. Pulse jet systems are used to maintain the filters of the dust collection system particulate-free. The collected material is eliminated and accumulated in drums. Zinc Zinc dust is produced in the galvanizing process.

A baghouse system is the preferred system. Rice Dirt Rice dirt has extremely great as well as minute fragments that build up throughout the manufacturing of rice-based products. A dirt collection system is needed for the defense and safety of workers. Silica Silica is just one of one of the most usual materials on earth. It is a central component of a number of manufacturing operations, such as the production of glass, ceramic tile, concrete, and also asphalt.